Summary of key points

- Supply chain emissions are a sizeable portion of an organisations emissions and need the level of attention to match this

- Supply chain engagement is a way to identify, measure and manage these emissions and is a common requirement for many emissions programmes

- Challenges exist, but this also presents significant opportunities for you and your suppliers. The key message is to make a start

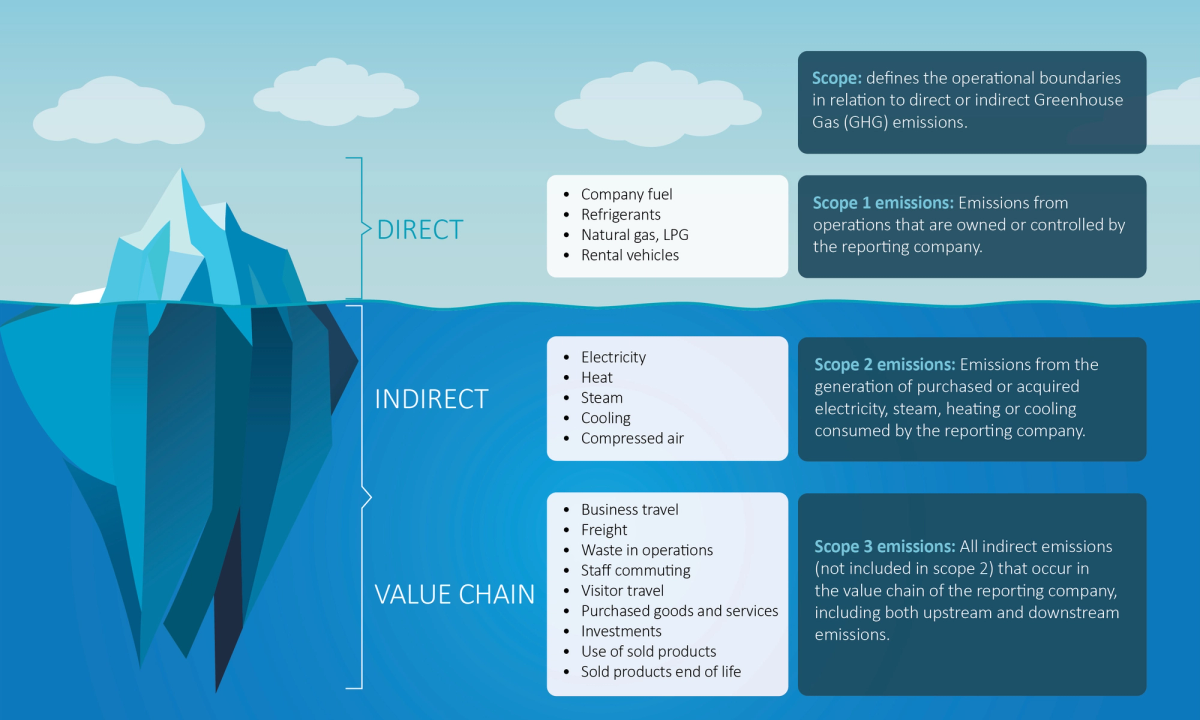

More New Zealand businesses are setting public net zero carbon targets and pledges with promised actions to tackle climate change. Until recently, most entities have focused their attention on carbon reduction within their own operations. However, we need to account for Greenhouse Gas (GHG) emissions across the supply chain and product lifecycle to speed up decarbonisation.

The increased demand for supply chain decarbonisation is providing organisations the opportunity to influence these indirect emission sources. Better accuracy across the supply chain is being driven largely by companies stepping up for positive change, others by a change in business strategy, investor scrutiny, or mandatory reporting on climate risks.

As seen in Figure 1, in most cases your supply chain will be a significant portion of your total emissions. A recent report found the average of Scope 3 is 11 times more than Scope 1 and 2. This highlights the opportunity to influence many suppliers, and ultimately reduce these indirect emission sources. And that’s good news.

Figure 1. Supply chain emissions are likely to represent a significant portion of total emissions

What is supply chain engagement?

Supply chain engagement, also known as supplier engagement, is the communication between organisations and suppliers to:

- Improve supply chain emission measurement accuracy and completeness, to identify hotspots; and

- Influence and reduce supply chain emissions

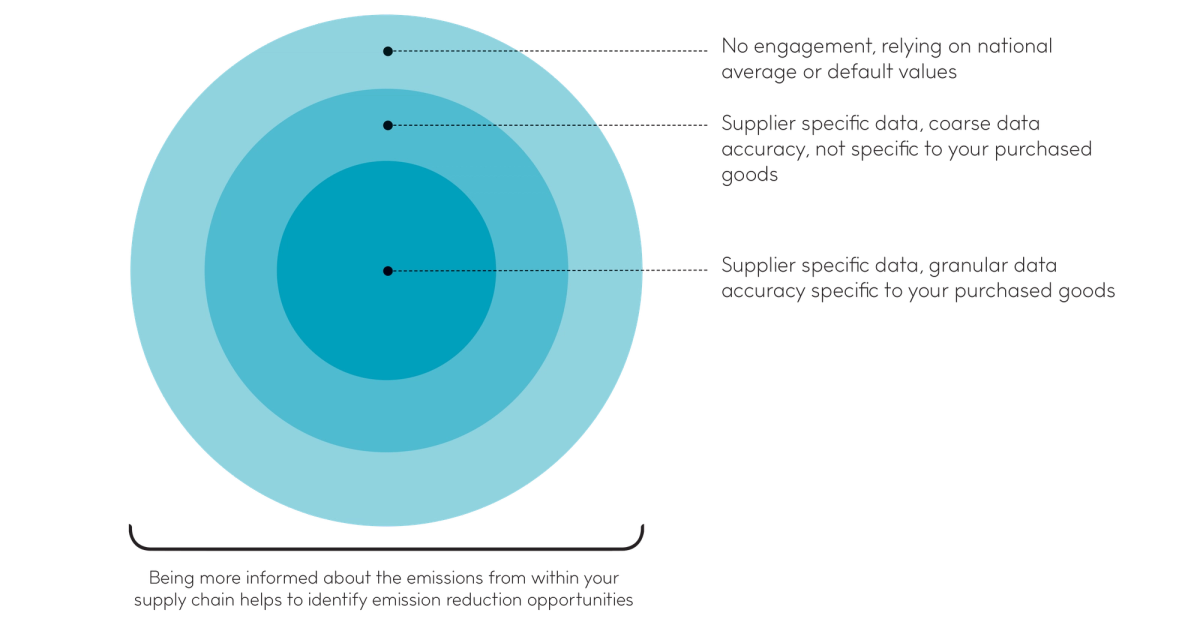

Through supply chain engagement, data accuracy and carbon accounting can shift the reliance from default sector factors to accurate supplier information, providing opportunities to influence and reduce emissions. Often Scope 3 emissions can be minimised with relatively straightforward measures, such as product and logistics optimisation and procurement.

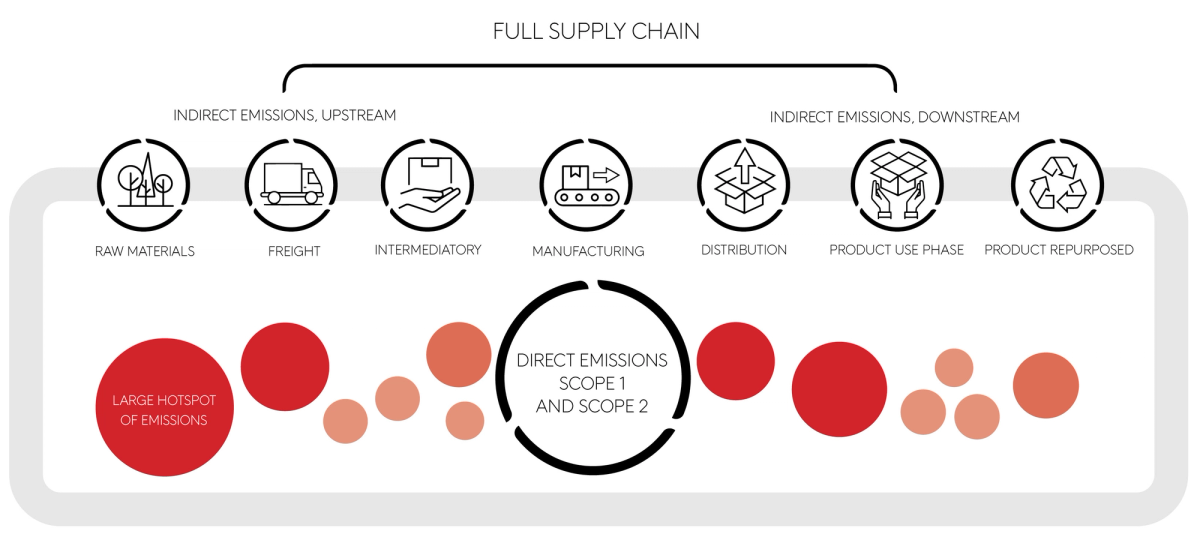

A fundamental first step to achieving net zero is measuring your supply chain emissions. These are often aligned with either the International Standards Organisation (ISO) 14064-1 or the Greenhouse Gas (GHG) Protocol. Mapping your emissions footprint by scale, and how much control you have over the source will be a good way to start engaging suppliers. Identifying emissions hotspots can help prioritise your supply chain decarbonisation strategy.

Figure 2. Improving the completeness and accuracy of your supply chain emissions can help identify emission hotspots for subsequent reduction opportunities.

We can even look into product specific factors for more detail (Figure 3). Product specific factors are particularly important if you’re working on product lifecycle measurements.

Figure 3. Data and emissions factor specificity.

What is the benefit and impact of supply chain engagement?

Given the significance of supply chains in most organisations’ GHG inventories, the opportunity to reduce emissions is extensive. To give a sense of the scale, the global disclosure system CDP had suppliers reporting 1.8 billion tCO2e in reductions for the 2021 reporting period.

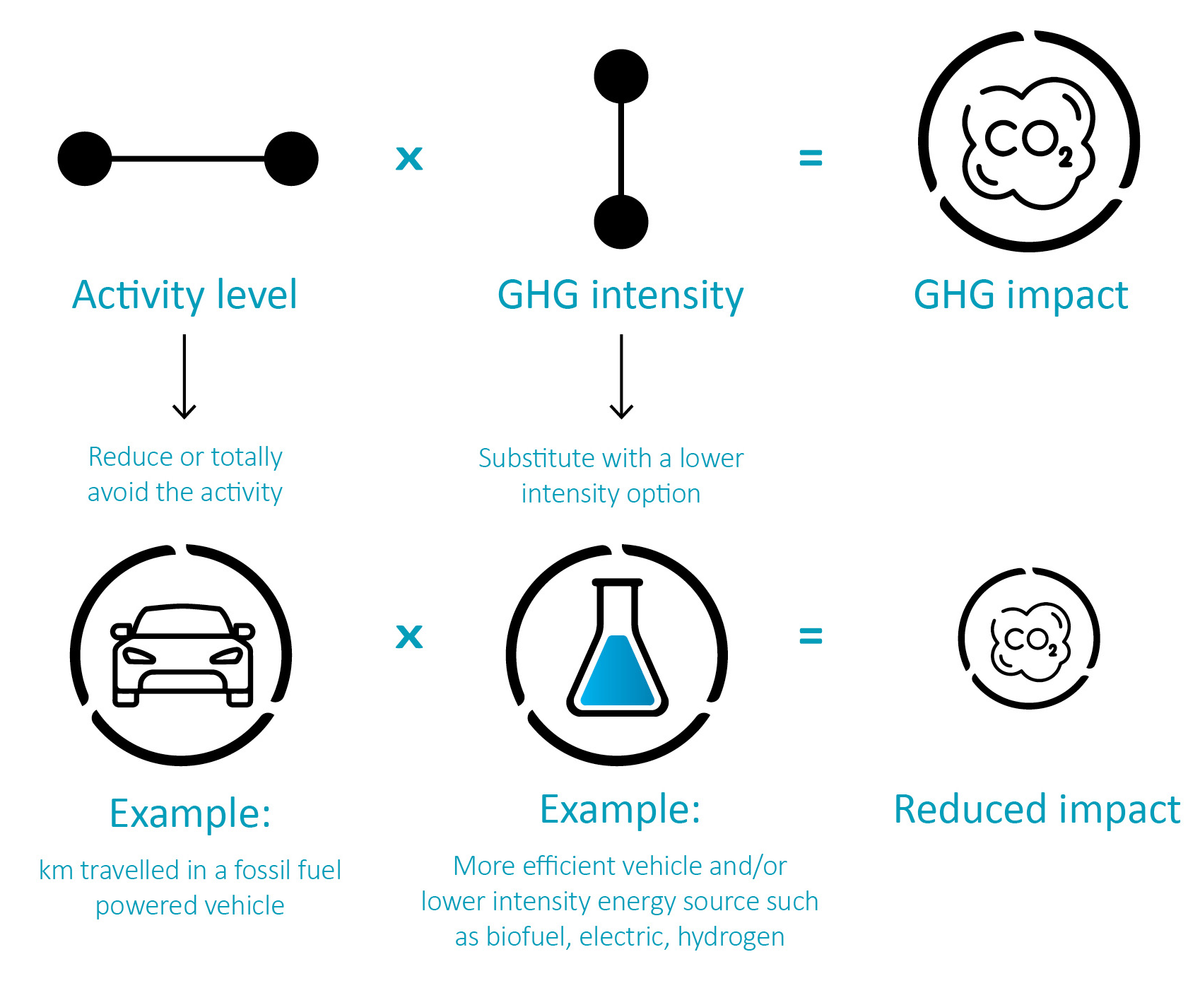

Reducing emissions can be done by either decreasing the activity level, or the greenhouse gas (GHG) emissions intensity, or both. Initial efforts are often focussed on reducing activity levels by reducing the quantity of raw materials through refining product design, or minimising wastage. However, the GHG intensity of the activity can also be reduced.

For a product, this might include working with an existing supplier to reduce the intensity of materials, switching to a less intensive supplier of the same material, or a lower intensity alternative material if existing providers aren’t willing to engage.

Figure 4. Key levers for reducing emissions in the supply chain.

What does effective supply chain engagement look like?

There are numerous initiatives and guidelines on supply chain engagement, and the alignment to one or several of these should be guided by the GHG inventory intended use and users. For example, the Toitū Climate Positive programme has set requirements on the subject, as does the Climate Leaders Coalition, Science Based Targets Initiative, and CDP.

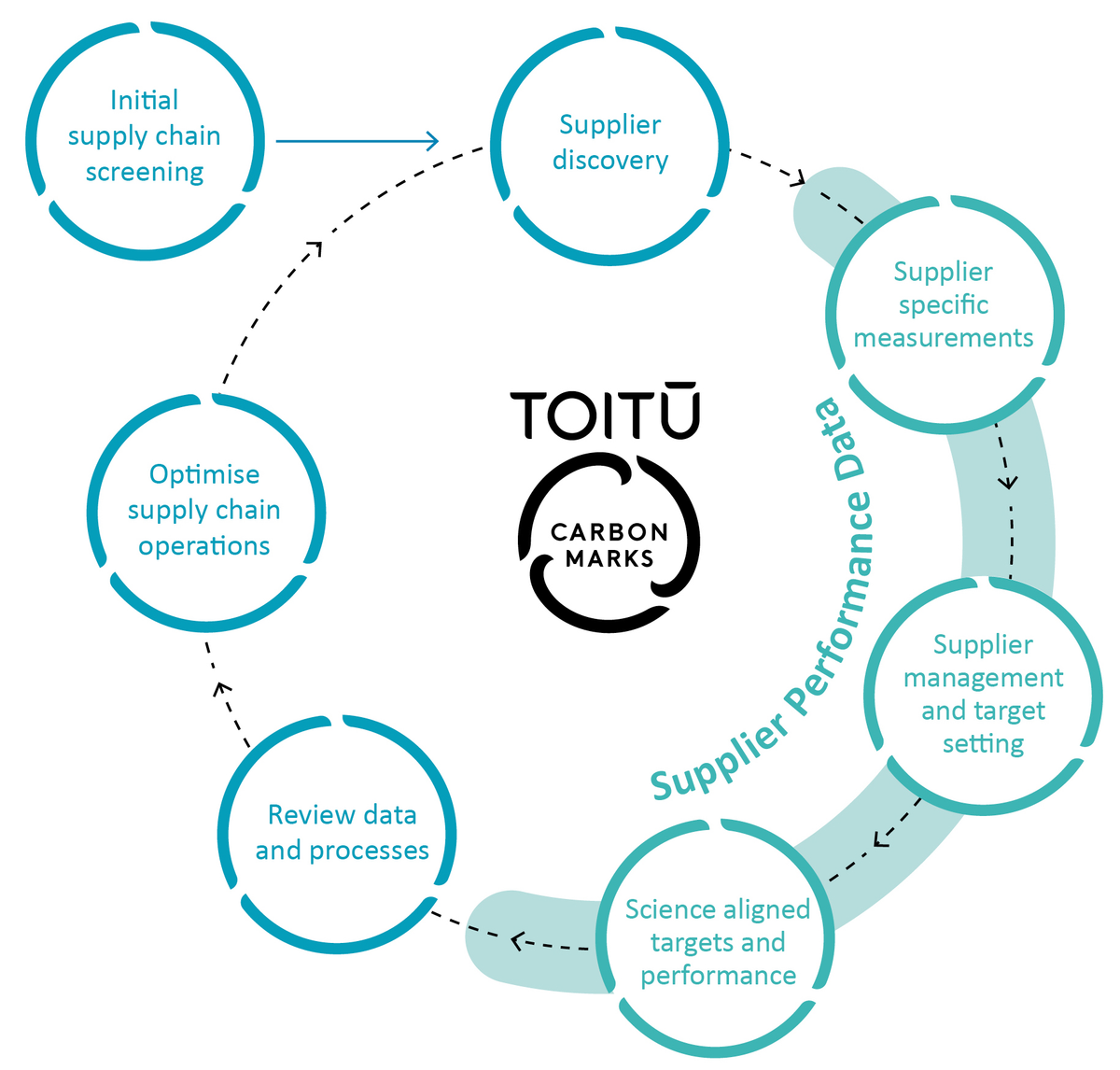

As an example, the Toitū Climate Positive programme recommends a step wise approach for supply chain engagement (Figure 5). For all steps 2-4, you should see a benefit in your own supply chain emissions via a feedback loop to enhance your initial screening estimate. Initial engagement with your supply chain will be dependent on scale and number of suppliers. Some examples of initial engagement can include:

- Creating a simple discovery questionnaire to suppliers to identify who currently measure and manage emissions, and details on scope and specificity of their measurement

- A success indicator tracking the proportion of your suppliers (by emissions) that are measuring and managing their emissions using ambitious science aligned targets.

- Workshops or training for some of the key suppliers to attend and ‘get on board’ with what your organisation is aiming to achieve

- Assessing potential methods to incorporate GHG efficiency into tendering processes to ensure that emissions are given an appropriate weighting in the procurement process; and

- Promoting programmes to your suppliers in carbon measurement and management. These could include Toitū Carbon Assess, Toitū net carbonzero, carbonreduce, or Climate Positive.

Figure 5. Step wise approach on supplier engagement. Green lines indicate cycling supplier data back to enhancing the original Scope 3 screening emissions estimate.

Other notable guidance and resources include the WBCSD Value Chain Transparency Pathfinder, The Carbon Call (emerging initiative), the Value Change in the Value Chain, and CDP Engaging the supply chain.

Your level of influence and control over suppliers will affect how much can be achieved as a standalone organisation. However, even in the context of large global corporates, there is increasing encouragement for pre-competitive collaboration in order to achieve the change needed at the scale and pace required, for example across a whole supply shed or sector. The global Sustainable Apparel Coalition, and, closer to home the SBCs Low Carbon Freight work group are examples of this.

Challenges and opportunities

There are challenges in implementing a complete supply chain engagement programme, due to factors such as data availability, consistency, collaboration, and willingness to participate. Complete and successful supply chain engagement is still in its infancy. For example, CDP noted that whilst year on year supply chain disclosure is steadily increasing, “only 20% [of its 11,000 companies submitting data] reported data for Scope 3 category 1 ‘Purchased Goods and Services’ emissions, and 62%aren’t engaging suppliers on the topic”. Additionally “suppliers may require a year or more to create the mechanisms required to collect data”. This reinforces the lead practice notion that organisations should simply get started, and accept low quality data in the first instance. This can then send signals along the supply chain to both refine measurements and identify reduction opportunities. CDP is seeing this trend for multiyear suppliers disclosing, with 34% of third year disclosers setting climate targets, as opposed to 24% for first year disclosers.

How you can get started

A natural starting point would be to communicate with your Tier 1 suppliers who you have a direct relationship with. Be sure to tailor your communications to suit your intended use and users, including alignment to any relevant programme requirements. Examples of initial communication could include:

- Explaining what you are trying to achieve

- Asking the supplier if they measure and manage their emissions

- If yes, can they share:

- Their Scope 1 and Scope 2 GHG emissions per $ that you spend (or per product if available)

- Disclosure of standard(s) used for measuring their emissions

- Verification status of the measured emissions

- Time period of the measured emissions

- What reduction targets they have

- If no, why not and are they willing to start?

Your most significant opportunities may be further along the supply chain, such as your Tier 2 or 3 suppliers. Starting with Tier 1 will trigger your Tier 1 suppliers to engage with their own Tier 1 suppliers, resulting in cascading action throughout the supply chain.

If there is a known common supply chain programme for the sector your supplier operates in, try to align your questions to a common format[5]. Keep sight of the longer-term goal. We are aiming to get more complete and accurate data, preferably with a Lifecycle Analysis component. From there, we want to see reduced emissions intensity and GHG reductions.

Over time, we can expect to see more transparency and disclosure within supply chains, with sufficient interoperability to align to various programmes and desired outcomes. We can expect to see more accuracy, ideally to product level[6], over time as data flows more freely in a digital accounting structures in an interoperable[7] format. Internationally, supplier engagement ratings and leader boards[8] are also emerging and could prove to be an important tool for amplifying action in this space.

Summary

Supply chain emissions are often a significant portion of your organisations total inventory, and hence an opportunity to go further on your decarbonisation mission. Supply chain engagement enables communication with suppliers to better understand your organisations’ indirect emissions and find ways to reduce them. Approaching engagement should be guided by your intended use and users, and alignment to relevant programmes. Challenges exist, but the key message is to get started. This can involve targeting your key suppliers with a basic set of questions to start the dialogue and then progress from there. Addressing Scope 3 indirect emissions from supply chain engagement is getting a lot of focus, and we can expect more development of initiatives and guidance to help with aligning to lead practice in this space.