Key points

- A Product Carbon Footprint (PCF) helps measure greenhouse gas (GHG) emissions from a product or service across its lifecycle

- Knowing your PCF helps identify and lower the GHG impact across a products’ lifecycle

- Defining the scope, building a lifecycle inventory, completing an impact assessment, and interpreting the results are all essential steps to gaining PCF certification. This helps provide a competitive advantage, gives visibility to emissions hotspots, and ensures you’re taking science aligned action.

What is a Product Carbon Footprint?

What total of greenhouse gas (GHG) emissions are associated with a product across its lifecycle? This is a question that is increasingly relevant, and a Product Carbon Footprint (PCF) can help find answers. A PCF measures the total GHG emissions of a product over its entire lifecycle. This holistic and robust analysis helps understand the climate impact that an organisations’ product and services are having, providing opportunity to reduce those impacts.

While often used in association with a Life Cycle Assessment (LCA), the difference between the two relates to the impact categories measured or analysed. A PCF is focused on one environmental impact category: GHG emissions. An LCA is an evaluation of all the environmental impacts and considers wider categories, such as ozone depletion, eutrophication, acidification, resource depletion etc. It can also extend into social impact areas if your organisation is interested in reporting beyond carbon metrics.

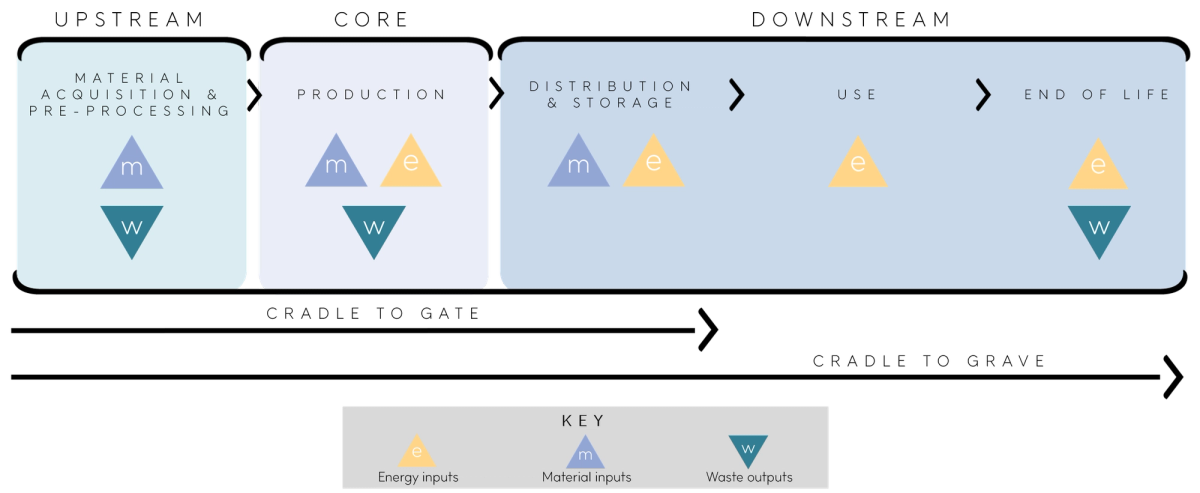

Undertaking a PCF is an excellent opportunity to engage with your supply chain, especially with increasing requirements to report on Scope 3 emissions, e.g. External Reporting Board, Carbon Neutral Government Programme. For most businesses, this will mean both upstream (raw materials, production phase) and downstream (the distribution, end product use, and disposal phases) aspects, outlined in Figure 1. These may not be areas that you have significant control over. However, Scope 3 emissions are often the largest emissions in a PCF, making it a great place to reduce emissions, improve product design, and have a lower environmental impact.

Figure 1: Diagram of upstream and downstream in relation to a product carbon footprint and cradle to gate and cradle to grave.

How to measure a PCF

Understanding your total PCF starts with defining the emissions scope or boundary to measure the impact of the product. The two most common types are:

Cradle to grave – accounting for carbon impacts at each stage of a product’s lifecycle. This includes operations, manufacturing, distribution, retail, how the product is used, and finally its disposal.

Cradle to gate – accounting for carbon impacts of a product from production until it reaches the factory gate. This is less common as it only measures a product from where it’s source to the business’s manufacturing the product. Any further use is then excluded.

The method for assessing the lifecycle GHG emissions of goods and services (jointly referred to as ‘products’) is based on internationally recognised standards (such as ISO 14040/44, ISO 14067, PAS 2050, GHG Product Life Cycle Standard).

The Toitū carbon product certification programme offers both cradle to gate and cradle to grave as options, and is aligned to the international standards PAS 2050 and ISO 14067.

How to calculate a PCF

The final number from a PCF is made up of the sum of GHG emissions (including GHG removals if there are any) in a product. It’s measured in CO2 equivalents per functional unit, which is specific to the product being audited. For example, this could be per litre for a beverage or per kilogram for a meat product.

There are generally four steps to completing a measurement, they are:

1.Define the goal and scope

Define what is within the boundary, the measurement period, and how you are going to report the emissions to make it comparable between similar products. For products, there are the two approaches to setting the boundary as mentioned (cradle-to-gate or cradle-to-grave). This comes down to whether you are measuring the final product, which a consumer would see, or whether it is a bulk product traded business-to-business.

2. Life cycle inventory

Now it’s time to find out where your emissions are coming from and collect the data. Under each life cycle stage of the product, identify all your activities, your suppliers and detail on the distribution and packaging. If you’re considering a Toitū carbon product certification, we’ll provide you with the framework and tools to identify this. Remember, we’re looking across the full lifecycle: ingredient and material inputs, production, distribution, storage, use, and waste disposal. For any emissions source, primary data is best. This means going back to the source of truth, like a data meter or a supplier invoice. For data outside of your direct control, talk to suppliers, but secondary data (e.g. database data, modelled data) may be needed.

3. Impact assessment

After completing the inventory you’ll have the activity data for each emission source. The impact assessment applies conversion factors to the data to transform this data into carbon dioxide equivalents

4. Interpretation of the results

Finally, the results are processed and interpreted. Hotspots within the product lifecycle can be identified and reductions tracked. Any limitations or uncertainty is noted to help focus on where the measurement could be improved in future.

If you do not have specific data for upstream processes, if you’re a Toitū member you can access our international databases and modelling to fill gaps. To be confident in your numbers, a PCF in line with international standards will help to develop a comprehensive assessment of the footprint, so you can identify the ‘hotspots’ across the supply-chain and distribution. Ongoing verified measurement against a consistent standard also means when you implement initiatives to reduce, you can track your results.

For businesses considering measuring their product carbon footprint and getting third party certification, the Toitū carbon product programme requires additional steps, including data measurement, an independent audit, developing a carbon reduction plan, and offsetting remaining emissions through verified carbon credits to achieve a neutral balance (or offset 125% of your total emissions through verified carbon credits to achieve a carbon positive impact).

What are the benefits of a product carbon footprint?

The reasons for undertaking a PCF vary and will differ between organisations. Some common reasons include:

- Identifying GHG hotspots within the product supply chain to reduce GHG impacts

- Helping businesses understand their impact on the environment, make better decisions regarding sustainability, and track their improvements over time

- Measuring eco-design within your products and to influence research and development

- Promoting good environmental and social practices

- Increased efficiency

- Meeting the demand from consumers and subcontractors for climate friendly products

- Facilitates more comprehensive reporting within an organisational footprint

- helping embed data collection within the organisation to ensure regular and more accurate reporting of GHG emissions

- Meeting the increasing demand of export markets factoring in this data. For example, proposals by the European Commission intend to apply carbon tariffs to some imported goods

- Carbon labelling for products can inform customers of the footprint of their purchased products

Over time, suppliers will increasingly be asked for this information and we expect data availability to follow suit. This will improve the transparency of emissions and raise the data quality of PCFs in general, as the findings from one product can help understand the emissions of another. Estimates will rely less on default database values for upstream emission sources, with product footprints incorporating more detailed and representative supplier specific emissions.

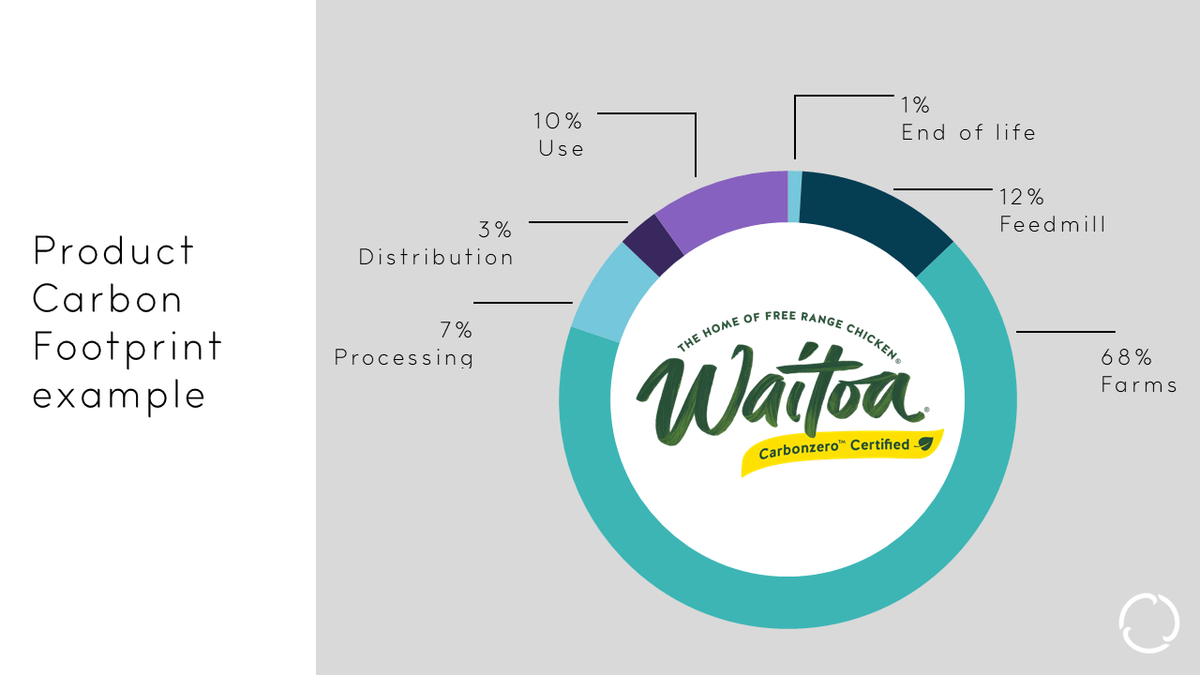

Case study: Waitoa chicken

Here’s an example for a net carbonzero product, Waitoa chicken. Upstream activities include growing the feed, fertiliser use, and transportation of the ingredients to farms. Core activities of the product include the energy and waste associated with manufacturing, packaging and storage. They then looked at downstream activities which include the transportation to point of sale, refrigeration at retailers and in a buyers’ home, cooking the chicken, and disposing of the packaging and food waste.

Figure 2. Lifecycle diagram for the Inghams Waitoa carbonzero chicken. Most emissions come from the farm, but nearly one third of emissions come from other sources that need to be measured and managed as a part of a PCF.

Summary

PCFs are a useful tool for measuring your products’ GHG emissions and, through Toitū certification, can be marketed as international best-practice and science led. It showcases a detailed and comprehensive assessment that accounts for all your emissions, including raw materials production, supply freight, manufacturing, packaging, distribution, usage, through to end-of-life.

Engaging with your supply chain to understand the extent of your carbon impacts and is crucial for accuracy and completeness for PCFs. It also results in a better understanding of the impacts your products may have on the environment. In turn, this creates further opportunities for emissions reductions. Using our extensive databases and dynamic modelling software, we can quantify hard-to-measure upstream emission sources. This gives confidence that our certification process provides a framework to reduce and later offset emissions if desired, as we strive to achieve our climate goals.

Glossary

Cradle to gate

Quantification, which includes the GHG emissions and removals arising up to the point at which the product leaves the organisation undertaking the assessment for transfer to another party

The assessment of a partial product life cycle from the raw resource (cradle) to the factory gate (i.e., before it is transported onwards into the supply chain or the consumer)

Toitū Envirocare

Cradle to grave

Quantifying emissions across a products’ full life cycle. Encompasses resource extraction (cradle) to the use phase and disposal phase (grave)

Toitū Envirocare

Ecodesign

The integration of environmental aspects into the product development process, by balancing ecological and economic requirements. Eco-design considers environmental aspects at all stages of the product development process, striving for products which make the lowest possible environmental impact throughout the product life cycle

UNEP, 2001

Environmental Product Declaration (EPD)

A claim which indicates the environmental aspects of a product or service

ISO 14025:2006

Functional unit

Quantified performance of a product system for use as a reference unit

ISO 14067:2018

Greenhouse gas (GHG)

Gaseous constituent of the atmosphere, both natural and anthropogenic, that absorbs and emits radiation at specific wavelengths within the spectrum of infrared radiation emitted by the Earth’s surface, the atmosphere and clouds

ISO 14067:2018

Life cycle assessment (LCA)

Life Cycle Assessment (LCA) is the quantitative evaluation of the environmental impacts of a product or service system through all stages of its life

Lifecycle Association of New Zealand

Life cycle impact assessment (LCIA)

Phase of life cycle assessment aimed at understanding and evaluating the magnitude and significance of the potential environmental impacts for a product system throughout the life cycle of the product

ISO 14067:2018

Product Carbon Footprint (PCF)

Sum of GHG emissions and GHG removals in a product system, expressed as CO2 equivalents and based on a life cycle assessment using the single impact category of climate change

ISO 14067:2018

Secondary data

Secondary data can include data from databases and published literature, default emission factors from national inventories, calculated data, estimates or other representative data, validated by competent authorities. Secondary data can include data obtained from proxy processes or estimates.

ISO 14067:2018